How Digital Twins Are Revolutionizing Supply Chains?

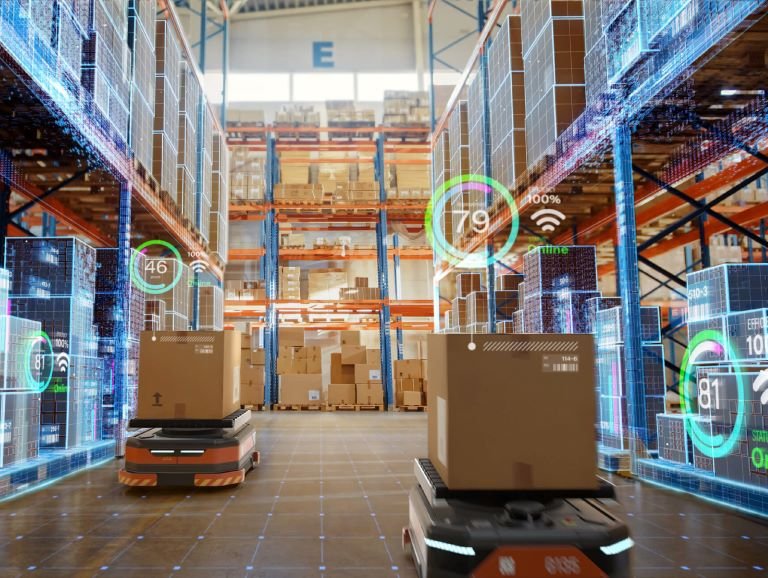

Digital twins are transforming the landscape of supply chain management by creating virtual replicas of physical assets, processes, and systems. This innovative technology enables businesses to simulate, analyze, and optimize their operations in real time. By providing a comprehensive view of the entire supply chain, digital twins empower organizations to make informed decisions, anticipate challenges, and enhance overall efficiency

One of the most significant benefits of digital twins is their ability to improve visibility across the supply chain. By integrating data from various sources—such as IoT sensors, ERP systems, and historical performance metrics—digital twins create a dynamic model that reflects the current state of operations. This real-time visibility allows companies to monitor inventory levels, track shipments, and analyze production processes. With a clearer understanding of their

supply chain, organizations can respond more swiftly to disruptions and adapt to changing market conditions

Furthermore, digital twins facilitate predictive analytics, enabling businesses to foresee potential issues before they arise. By simulating different scenarios and analyzing the outcomes, companies can identify bottlenecks, optimize resource allocation, and improve demand forecasting. This proactive approach reduces the risk of supply chain disruptions, ultimately leading to enhanced customer satisfaction and reduced operational costs. As businesses increasingly rely on data-driven insights, digital twins serve as a vital tool for strategic planning and risk management.

In addition to operational improvements, digital twins are also driving innovation in product development and lifecycle management. By testing and validating new products in a virtual environment, companies can streamline their design processes and reduce time-to-market. This capability not only enhances product quality but also fosters collaboration among teams, as stakeholders can visualize changes and evaluate impacts more effectively. As digital twin technology continues to evolve, its potential to revolutionize supply chains will only grow, paving the way for smarter, more resilient operations in the future.